OEM/ODM Factory Non Woven Handle Loop Stitching Machine - Fastly delivery nonwoven fabric cloth produce line melt blown fabric making machine equipment – Meiben

OEM/ODM Factory Non Woven Handle Loop Stitching Machine - Fastly delivery nonwoven fabric cloth produce line melt blown fabric making machine equipment – Meiben Detail:

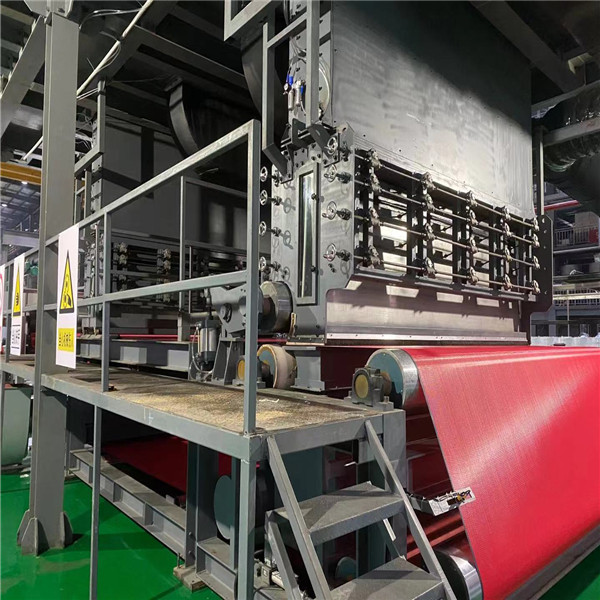

Fastly delivery nonwoven fabric cloth produce line melt blown fabric making machine equipment

Polypropylene non-woven fabric machinery and equipment: polymer (polypropylene + recycle)-large screw high temperature melt extrusion-filter-metering pump (quantitative delivery)-spinning (up and down drawing suction at the spinning inlet )——Cooling——Air traction——Net curtain forming——Up and down rollers (pre-reinforcement)——Hot rolling (reinforcement) of rolling mill——Winding——Inverted cloth slitting——Weighing and packaging——Incoming finished products Library

Process flow view of polypropylene non-woven fabric processing equipment

Non-woven production line model

SS(Prodnct width) 1600mm 2400mm 3200mm

Equipment 29x13x10m 30x14x10m 32x15x10m

Speed 350m/min 350m/min 30m/min

Gram Weighht 10-150g/m2 10-150g/m2 10-150g/m2

Yield(Products according to 20g/M2) 9-10T/Days 13-14T/Days 18-19T/Days

ITEM EFFECTIVE WIDTH GSM ANNUAL OUTPUT EMBOSSING PATTERN

S 1600MM 8-200 1500T Diamond, oval, cross and line

S 2400MM 8-200 2400T Diamond, oval, cross and line

S 3200MM 8-200 3000T Diamond, oval, cross and line

SS 1600MM 10-200 2500T Diamond, oval, cross and line

SS 2400MM 10-200 3300T Diamond, oval, cross and line

SS 3200MM 10-200 5000T Diamond, oval, cross and line

SMS 1600MM 15-200 2750T Diamond and oval

SMS 2400MM 15-200 3630T Diamond and oval

SMS 3200MM 15-200 5500T Diamond and oval

Polypropylene non-woven fabric processing equipment

Spunbond non-woven fabric features: high strength, good high temperature resistance (can be used for a long time in a 150 ℃ environment), aging resistance, UV resistance, high elongation, good stability and air permeability, corrosion resistance, sound insulation, mothproof, Non-toxic.

PP spunbond non-woven fabric

Material: PP polypropylene

Classification: SS, SSS

Color: blue, white, yellow

Application: Medical and health

As a kind of mechanical equipment, the spunbond non-woven production line is still widely used in our lives, but the spunbond non-woven production line also needs maintenance. Let’s take a brief look. First of all, the main maintenance content of the spunbond non-woven production line is cleaning, tightening, adjustment, lubrication, and anti-corrosion. Secondly, the mechanical department of each project needs to strictly perform various maintenance tasks according to the specified cycle according to the maintenance manual and maintenance procedures of the mechanical equipment, reduce the wear rate of the parts, eliminate the hidden dangers of failure, and extend the service life of the machinery. Routine maintenance is required, focusing on cleaning, lubrication, inspection and tightening. Routine inspection and maintenance should be carried out as required before, during and after each shift. Routine maintenance is done independently by the mechanical operator, and proper maintenance is required on a regular basis.

This is the end of the editor about the maintenance of the spunbond nonwoven production line. I believe everyone knows that the spunbond nonwoven production line has a long service life, so the spunbond nonwoven production line needs to be maintained and maintained. Work, only by doing a good job in maintenance can extend the use of the equipment

Product detail pictures:

Related Product Guide:

Along with the "Client-Oriented" small business philosophy, a rigorous high-quality handle system, highly developed producing machines and a powerful R&D group, we always supply high-quality products and solutions, fantastic services and aggressive costs for OEM/ODM Factory Non Woven Handle Loop Stitching Machine - Fastly delivery nonwoven fabric cloth produce line melt blown fabric making machine equipment – Meiben , The product will supply to all over the world, such as: Honduras, Guinea, Guyana, Please feel cost-free to send us your specifications and we'll respond to you asap. We've got a professional engineering team to serve for the every single detailed needs. Free samples may be sent for you personally to know far more facts. So that you can meet your desires, please really feel cost-free to contact us. You could send us emails and call us straight. Additionally, we welcome visits to our factory from all over the world for much better recognizing of our corporation. nd merchandise. In our trade with merchants of several countries, we often adhere to the principle of equality and mutual advantage. It is our hope to market, by joint efforts, both trade and friendship to our mutual benefit. We look forward to getting your inquiries.

Adhering to the business principle of mutual benefits, we have a happy and successful transaction, we think we will be the best business partner.