OEM Supply Non Woven Needle Punching Machine - SMS PP Spunbond Meltblown Composite Nonwoven Fabric Making Production Machinery Line For wet tissue – Meiben

OEM Supply Non Woven Needle Punching Machine - SMS PP Spunbond Meltblown Composite Nonwoven Fabric Making Production Machinery Line For wet tissue – Meiben Detail:

Product rendering

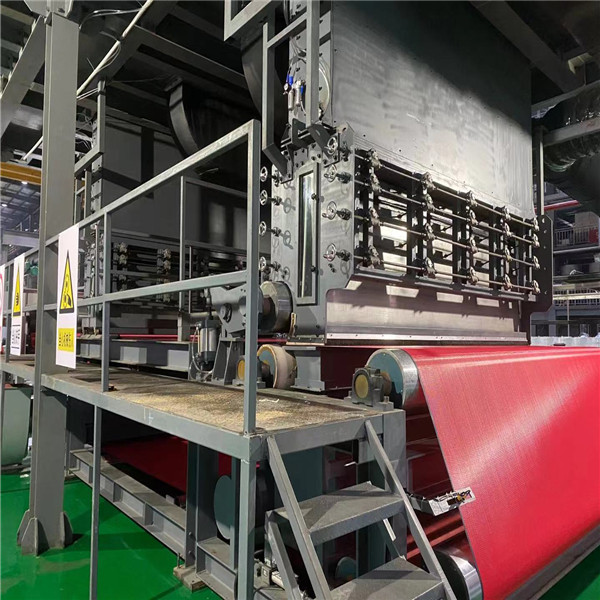

SMS nonwoven production line

SMS fabrics are widely used in different fields, such as medical care, sanitary materials, health care, S or SS fabrics can be used in facial masks, agriculture, construction, packaging, home textiles, etc.

Polypropylene spunbond nonwoven production line

The polypropylene spunbonded non-woven fabric production line produced by our company has been widely adopted by famous non-woven fabric manufacturers in my country, and exported to Europe, Asia, Africa and the Americas.

Native use

This machine is suitable for the production of polypropylene fiber spun into a net, hot-rolled and reinforced non-woven fabric, and its products can be used in medical and health, construction, geotechnical, agricultural and other industries as well as household materials

The main technical parameters

Product form: S, SS, SSS, SMS, SMMS, SSMMS

Width: 1600, 2400, 3200 (mm)

Spunbond monofilament size: 1.5dte~2.5dtex

Meltblown monofilament size: 1.0~2.0η

Finished book weight: S 10g~150g/㎡

SS 10g~70g/㎡

SSS 11g~70g/㎡

SMS 10g~70g/㎡

SMMS 12g~70g/㎡

SSMMS 15g~70g/

Maximum mechanical speed: S 150m/min

SS 350m/min

SSS 450m/min

SMS 450m/min

SMMS 450m/min

SSMMS 450m/min

| ITEM | EFFECTIVE WIDTH | GSM | ANNUAL OUTPUT | EMBOSSING PATTERN |

| S | 1600MM | 8-200 | 1500T | Diamond, oval, cross and line |

| S | 2400MM | 8-200 | 2400T | Diamond, oval, cross and line |

| S | 3200MM | 8-200 | 3000T | Diamond, oval, cross and line |

| SS | 1600MM | 10-200 | 2500T | Diamond, oval, cross and line |

| SS | 2400MM | 10-200 | 3300T | Diamond, oval, cross and line |

| SS | 3200MM | 10-200 | 5000T | Diamond, oval, cross and line |

| SMS | 1600MM | 15-200 | 2750T | Diamond and oval |

| SMS | 2400MM | 15-200 | 3630T | Diamond and oval |

| SMS | 3200MM | 15-200 | 5500T | Diamond and oval |

Nonwoven production details

Features of this machine

1. The material suction, metering and mixing device adopts frequency conversion control, which is accurate and reliable; the material level exceeds the limit and automatically alarms.

2. The screw extruder adopts a high-precision helical gear reducer. Electricity adopts three closed-loop control, so that the extruder has the characteristics of high precision, high reliability, high safety performance and long service life.

3. The melt pipeline adopts the electric heating form, and the heat preservation material is outside, which has the characteristics of short melt flow and automatic control of heating and heat preservation.

4. The spinning die is of an overall slit structure, and a special melt distribution cavity is adopted, so that the melt is evenly distributed. The whole spray plate is used to make the tow distribution evenly.

5. Side blowing adopts double-sided symmetrical blowing structure, and multi-layer rectifying device is installed in the air duct.

6. The drafting air duct adopts a slit type to draft the tow by airflow. The lower draft air duct, the diffuse air duct, the width of which is adjustable.

7. The netting machine is composed of main drive, net curtain, frame, suction duct, correction device, tensioning device and other parts.

8. The suction and diffusion air ducts are separated from the environment under the action of brushes and sealing rollers, forming separate controls to meet different process requirements.

9. Advanced automatic control. The entire production line adopts industrial computer to monitor and manage the entire technological process. Use PLC to control the entire production line. The Profibus process field bus is used to communicate with various frequency converters of the production line such as screw extruder, spinning machine, netting machine, hot rolling mill, winder, etc., and communicate with the temperature control module of the production line through the communication board.

10. It can display the schematic diagram of the equipment process, the main process parameters (screw temperature, melt pipe temperature, die zone temperature, metering pump speed, netting machine speed, hot rolling mill speed, process parameters of the air conditioner used in the spunbond system, melting The setting value and measurement value of the hot air system equipment used in the jet spinning system, such as the spinning process parameters, and the alarm value of each control point. Can display the trend chart of craft history books, and can print craft history data.

11. The polypropylene spunbond non-woven fabric production line adopts single hanger die technology and a proprietary cooling and blowing rectification system, combined with advanced air drafting technology and high-speed web forming technology, plus a digital control system, so that the product uniformity is good, It has the advantages of fine size, high vertical and horizontal strength, and low energy consumption. The overall performance of the production line has reached the advanced technical level of similar foreign equipment

Product detail pictures:

Related Product Guide:

High quality Initial,and Buyer Supreme is our guideline to offer the ideal assistance to our shoppers.At present, we are striving our best to become amongst the ideal exporters inside our industry to satisfy shoppers more want for OEM Supply Non Woven Needle Punching Machine - SMS PP Spunbond Meltblown Composite Nonwoven Fabric Making Production Machinery Line For wet tissue – Meiben , The product will supply to all over the world, such as: Ecuador, Paraguay, New Zealand, We've got more than 10 years experience of production and export business. We always develop and design kinds of novel items to meet the market demand and help the guests continuously by updating our goods. We've been specialized manufacturer and exporter in China. Wherever you are, make sure you join us, and together we will shape a bright future in your business field!

This company can be well to meet our needs on product quantity and delivery time, so we always choose them when we have procurement requirements.