OEM Factory for Isolation Clothing Fabric Production Line - SS Nonwoven Production Lines SMS Spunmelt Nonwoven Making Machine Fabric Production Lines Equipment – Meiben

OEM Factory for Isolation Clothing Fabric Production Line - SS Nonwoven Production Lines SMS Spunmelt Nonwoven Making Machine Fabric Production Lines Equipment – Meiben Detail:

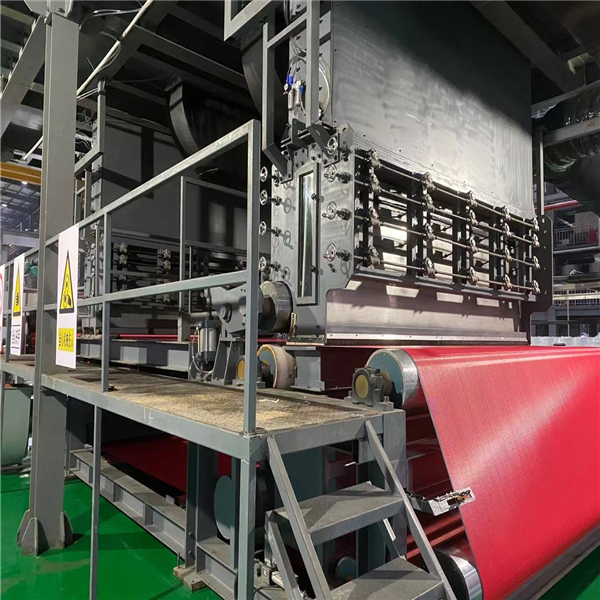

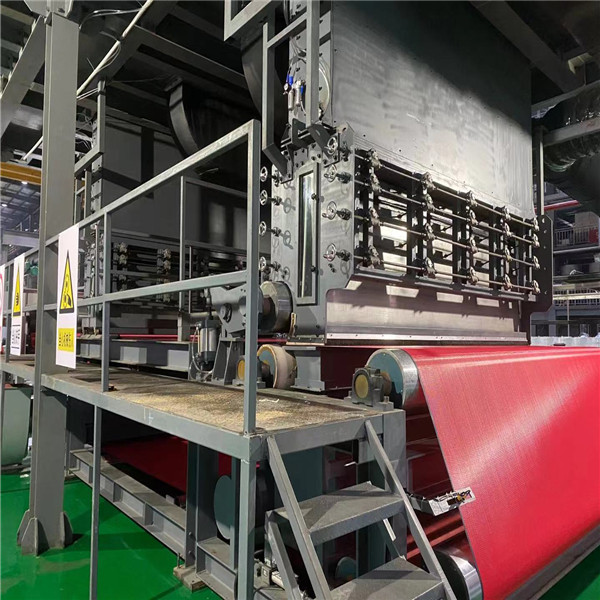

SS Nonwoven Production Lines SMS Spunmelt Nonwoven Making Machine Fabric Production Lines Equipment

Meltblown non-woven fabric plays a role of isolation and filtration in the mask, protects the human body from the invasion of dust, bacteria, and viruses, reduces various infections, and effectively protects human health.

Meltblown non-woven fabrics are mainly used for medical and health materials, filter materials, insulation materials, oil-absorbing materials, battery diaphragm materials, environmental protection materials, clothing materials, wiping materials, etc.

Product rendering

Non-woven machine production process

2. Scope of application:

Used in the production of meltblown non-woven fabrics.

Meltblown non-woven fabric plays a role of isolation and filtration in the mask, protects the human body from the invasion of dust, bacteria, and viruses, reduces various infections, and effectively protects human health.

Meltblown non-woven fabrics are mainly used in medical and sanitary materials, filter materials, thermal insulation materials, oil-absorbing materials, battery diaphragm materials, environmental protection materials, clothing materials, wiping materials, etc.

Non-woven machinery equipment specifications

| SS(Prodnct width) | 1600mm | 2400mm | 3200mm |

| Equipment | 29x13x10m | 30x14x10m | 32x15x10m |

| Speed | 350m/min | 350m/min | 30m/min |

| Gram Weighht | 10-150g/m2 | 10-150g/m2 | 10-150g/m2 |

| Yield(Products according to 20g/M2) | 9-10T/Days | 13-14T/Days | 18-19T/Days |

| ITEM | EFFECTIVE WIDTH | GSM | ANNUAL OUTPUT | EMBOSSING PATTERN |

| S | 1600MM | 8-200 | 1500T | Diamond, oval, cross and line |

| S | 2400MM | 8-200 | 2400T | Diamond, oval, cross and line |

| S | 3200MM | 8-200 | 3000T | Diamond, oval, cross and line |

| SS | 1600MM | 10-200 | 2500T | Diamond, oval, cross and line |

| SS | 2400MM | 10-200 | 3300T | Diamond, oval, cross and line |

| SS | 3200MM | 10-200 | 5000T | Diamond, oval, cross and line |

| SMS | 1600MM | 15-200 | 2750T | Diamond and oval |

| SMS | 2400MM | 15-200 | 3630T | Diamond and oval |

| SMS | 3200MM | 15-200 | 5500T | Diamond and oval |

Shipping packaging

3. The technical process of the production line

Material automatic feeder

Screw extruder

Melt filter

Metering pumps

Meltblown die head

Net curtain

Electric electret machine

Rewinding and trimming machine

4. Our services (packaging and delivery; one-year warranty; remote control, customer customization, etc.).

one year warranty

remote control

Commissioning and training

Turnkey projects

Your profile

Meltblown non-woven fabric is a kind of ultra-fine fiber non-woven fabric, which is stretched by strong hot air. The fiber diameter is about 2 microns, which is the thinnest of all fibers.

Because of its special structure and polypropylene raw materials, meltblown nonwovens have good waterproof and air permeability.

The filtration efficiency is high, and it integrates the functions of bacteria isolation, poison filtration, heat insulation, warmth, heat preservation, non-toxic and non-irritating.

Uses are generally in the fields of filter materials, oil-absorbing materials, and sanitary materials.

Product name: Meltblown fabric

Material: 100% polypropylene

Weight: 20G-40G

Width: 175mm / 260mm

Uses: medical and health

MOQ: 500KG

BFE/PFE: 95+/99+

1. Various non-woven equipment systems, direct and cross configuration

2. Single source solution

3. Comprehensive project management

4. Experience and expertise

5. High-capacity industrial production lines and top-quality products

6. Solutions for unique ultra-light products

7. Combining dehydration and drying technology to reduce energy consumption

8. Revolutionary design with a maximum speed of 400 m/min

9. Efficient water circulation and filtration

10. A full range of pattern solutions can customize your non-woven fabric

11. A complete nonwoven technology center provides full flexibility for testing, product development, market testing and training

has ten years of production technology experience, specializing in the

production of S/SS/SSS/SMS/SMMS PP Spunbond nonwoven fabric production line and various nonwoven fabrics.

Cooperation case: more than 100 production lines

Exports: Asia, Europe, America and other overseas regions

Team: foreign after-sales team

The spunbond non-woven fabric production line is a set of fiber mixing, carding, cross-laying, and then spunbonding, drying, winding, and slitting into fibers. Starting from the mixing, opening and cleaning of raw materials, various independent machines have been designed in series to meet the requirements of weighing, mixing, opening and cleaning of various fibers, as well as continuous and uniform deliver

Product detail pictures:

Related Product Guide:

Our primary purpose is to give our shoppers a serious and responsible company relationship, giving personalized attention to all of them for OEM Factory for Isolation Clothing Fabric Production Line - SS Nonwoven Production Lines SMS Spunmelt Nonwoven Making Machine Fabric Production Lines Equipment – Meiben , The product will supply to all over the world, such as: Swansea, Germany, Iran, To meet the requirements of specific customers for each bit more perfect service and stable quality merchandise. We warmly welcome customers around the world to visit us, with our multi-faceted cooperation, and jointly develop new markets, create a brilliant future!

We feel easy to cooperate with this company, the supplier is very responsible, thanks.There will be more in-depth cooperation.