2021 Latest Design Pp Spunbond Nonwoven Production Line - Spunmelt composite nonwoven production line, spunbonded nonwoven production line – Meiben

2021 Latest Design Pp Spunbond Nonwoven Production Line - Spunmelt composite nonwoven production line, spunbonded nonwoven production line – Meiben Detail:

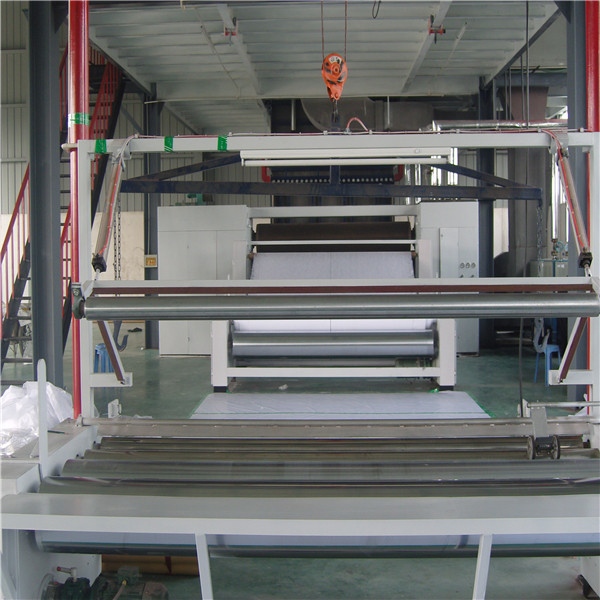

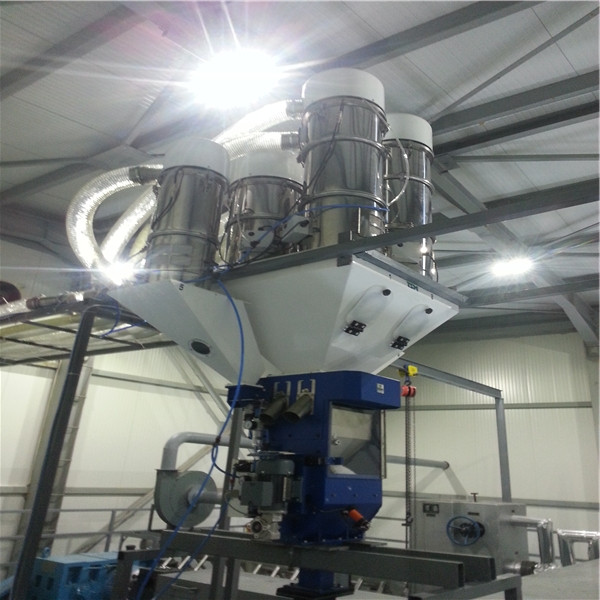

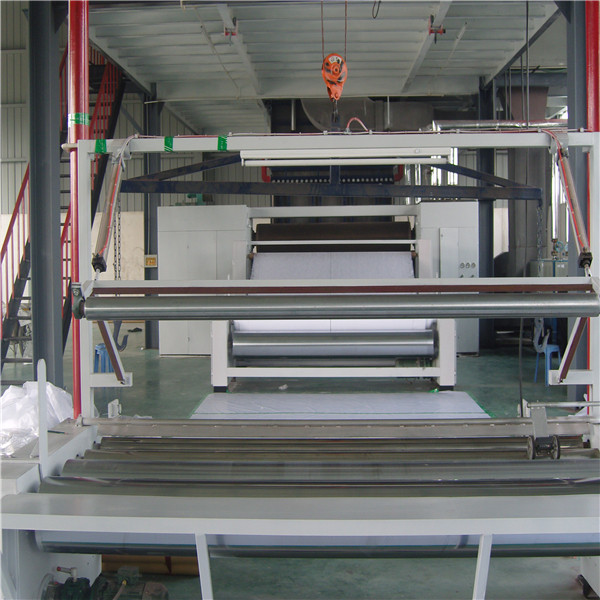

Meltblown nonwoven production line

Advantages of non-woven equipment

1. The entire process flow of non-woven equipment can be fully automated, and only 1~2 people are required to operate, which can save limited labor.

2. The non-woven fabric equipment can adjust the production speed and product size within the range. The non-woven fabric equipment uses touch screen operation, equipped with stepping fixed length, photoelectric tracking, automatic counting and automatic punching, etc.

3. In order to further realize the energy-saving effect of non-woven equipment, the non-woven equipment has the function of recycling surplus materials during the production process of the non-woven equipment, which automatically collects the remaining waste during the production process, which is helpful for secondary utilization and reduces labor intensity. Increased work efficiency. The recovery of waste materials not only saves resources, but also has a good protective effect on the environment.

Non-woven equipment

Non-woven equipment specifications

| ITEM | EFFECTIVE WIDTH | GSM | ANNUAL OUTPUT | EMBOSSING PATTERN |

| S | 1600MM | 8-200 | 1500T | Diamond, oval, cross and line |

| S | 2400MM | 8-200 | 2400T | Diamond, oval, cross and line |

| S | 3200MM | 8-200 | 3000T | Diamond, oval, cross and line |

| SS | 1600MM | 10-200 | 2500T | Diamond, oval, cross and line |

| SS | 2400MM | 10-200 | 3300T | Diamond, oval, cross and line |

| SS | 3200MM | 10-200 | 5000T | Diamond, oval, cross and line |

| SMS | 1600MM | 15-200 | 2750T | Diamond and oval |

| SMS | 2400MM | 15-200 | 3630T | Diamond and oval |

| SMS | 3200MM | 15-200 | 5500T | Diamond and oval |

Non-woven equipment delivery packaging

Operation and maintenance requirements of spunbond nonwoven production line

(1) There are many important parts on the spunbond non-woven production line, these parts need to be placed in place after use, and the instrument needs to be zeroed. The spunbond non-woven fabric production line should not be stacked with flammable and explosive materials, and no extraneous debris should be placed on the spunbond non-woven fabric production line. The countertop should be kept clean, and some oil and rust stains should be wiped clean.

(2) The internal mechanical parts of the spunbond non-woven production line are not as good as bearings, gears, etc., which need to be carefully checked during the operation and maintenance process, and to ensure that these parts can operate normally. For some parts that are relatively easy to wear and have failed, they must be mechanically replaced in time. The motors, gear boxes, synchronizing wheels, etc. of the spunbond non-woven fabric production line must be thoroughly maintained, and the circuits and mechanical mechanisms inside must be cleaned and adjusted.

(3) The spunbond non-woven production line sometimes has a lot of faults. Some faults, such as abnormal noises, track jams, etc., can be eliminated by manual operation. For some parts with frequent internal transmission, some lubricating oil can be added to ensure the smooth operation of machinery and equipment.

Product detail pictures:

Related Product Guide:

We not only will try our greatest to offer superb companies to just about every buyer, but also are ready to receive any suggestion offered by our shoppers for 2021 Latest Design Pp Spunbond Nonwoven Production Line - Spunmelt composite nonwoven production line, spunbonded nonwoven production line – Meiben , The product will supply to all over the world, such as: Provence, kazan, Florida, We believe in quality and customer satisfaction achieved by a team of highly dedicated individuals. The team of our company with the use of cutting-edge technologies delivers impeccable quality products supremely adored and appreciated by our customers worldwide.

Products and services are very good, our leader is very satisfied with this procurement, it is better than we expected,